03/10/2017 09:52

Imperial Tobacco Sees an Immediate Return on Investment with DiSupply

Larger Distribution/Retail chains are already using various inventory and order management systems. However, this was not the case with Imperial Tobacco’s Canada-wide network of 17,000 independent Retailers, who were frequently running out of stock. These systems are complex and expensive, placing them beyond the reach of independent Distributors/Retailers. As a result of this technological gap, Distributors/Retails found themselves lagging behind the big chains and losing competitiveness.

For many years, representatives of Imperial Tobacco visited these Distributors/Retailers about once a week, but the time it took to inventory and replenish stock reduced the time reps could spend helping Distributors/Retailers better manage Imperial Tobacco’s products. Entering data in the Customer Relationship Management (CRM) system also ate up a lot of time.

The DiSupply solution

Imperial Tobacco wanted to help Distributors/Retailers prevent stock shortages and give representatives more time to focus on business development. Furthermore, the solution would have to be integrated with Imperial Tobacco’s corporate data warehouse, as well as fit with the company’s business procedures and the technology available to Distributors/Retailers. But no solutions on the market fit the bill!

That’s when the company asked DiCentral, a long-standing partner, for help. Danny Slater, manager, marketing business intelligence at Imperial Tobacco, explains, “We have been working with DiCentral for almost 10 years, so this was a natural extension of a business partnership that began when we first started using DiCentral’s EDI solution.”

DiSupply is a web solution designed for the distribution/retail industry. It facilitates inventory and order management, and speeds up processing of orders for Distributors and Retailers. This simple and efficient tool gives users the information they need to make better business decisions.

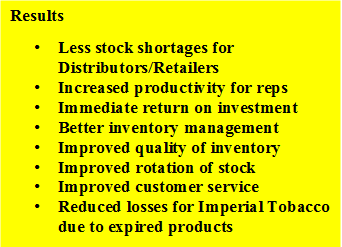

Dramatically less stock shortages

Since they started using DiSupply for inventory, “many Distributors/Retailers no longer run out of stock. Others still sometimes do, but much less frequently than before,” confirms Slater.

An integrated approach for implementation

Imperial Tobacco got its representatives involved in the process from the very beginning and throughout each stage of the project, from the pilot prototype to the technology roll-out with independent Distributors/Retailers. Instead of simply reacting, reps were proactive and quickly learned the importance of the new role they would be playing. Clerical tasks were reduced and the extra time that representatives now had with Distributors/Retailers changed their working relationships.

Faced with quick implementation of DiSupply with

Distributors/Retailers and order volumes that were higher than expected, DiCentral had to make adjustments in order to boost processing capacity and ensure a good user experience. “We were victims of our own success,” observes Slater. “Growth moved faster than we expected.”

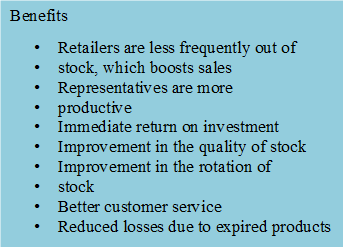

Results and benefits

“The return on investment was almost immediate. In fact, we reduced stock shortages more than we thought and the productivity of our team of representatives has risen higher than what we first estimated,” concludes Slater.